In an average year we test 3,500 pairs for our style qualification process."

In creating its breathable, waterproof footwear, GORE-TEX products are subjected to extreme quality assurance testing to ensure that every shoe made with its materials meets its rigorous standards—and those of its everyday wearers.  "We make sure we deliver what we are promising to deliver," says Donna Purner, who works in the company's footwear lab, "making sure that the consumer needs are being met both for waterproof and climate comfort as well as from an overall shoe perspective." Every new shoe model featuring GORE-TEX SURROUND® product technology is subjected to a battery of tests at one of the brand's three footwear labs around the world. There, the shoe enters a process that checks whole boot (or shoe) comfort, waterproofness and flex. "In an average year we test 3,500 pairs for our style qualification process and another 3,500 pairs through audits," Purner said. "We also provide key testing equipment to our factories so they can monitor the waterproofness of the footwear being made daily." Some of that equipment includes a centrifugal tester where boots are filled with water and spun at high speeds. The resulting pressure forces water through any holes that would become leaks in finished footwear. Labs also use an artificial "sweating" foot, which is placed in the shoe to test moisture loss. And as the brand evolves—for instance, the introduction of GORE-TEX SURROUND® product technology, which allows for breathability through the sole as well as the upper part of the shoe—so do the testing measures at its labs and partner and client facilities. As for walking a mile? That's gone high-tech too. All GORE-TEX brand styles must pass the mechanical boot flex test, in which mechanized feet flex the prototype shoe up to 200,000 times to simulate about 250 miles of walking. To add an extra stressor, the test is executed partially underwater. Sure, it's a lot of work, but the first step in meeting customer expectations—especially when your customers expect high-level waterproof performance in a comfortable package—is putting on their shoes.

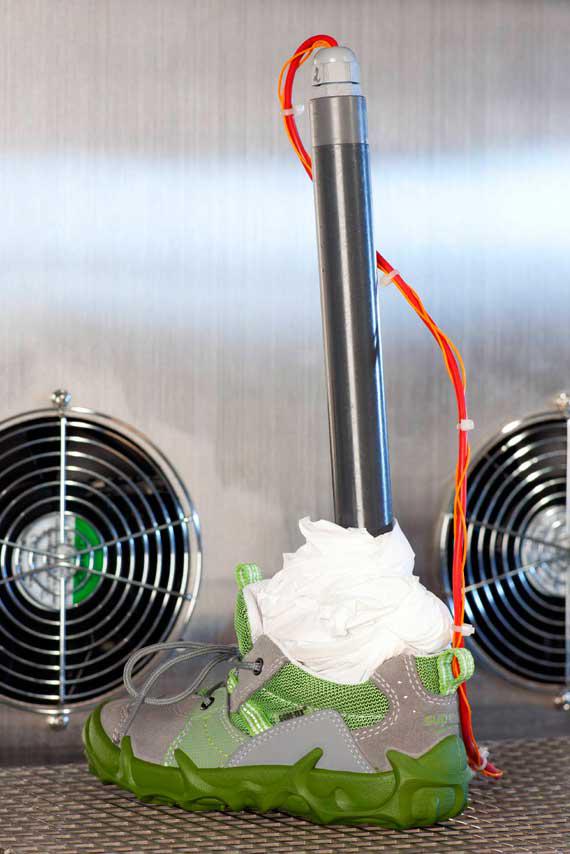

"We make sure we deliver what we are promising to deliver," says Donna Purner, who works in the company's footwear lab, "making sure that the consumer needs are being met both for waterproof and climate comfort as well as from an overall shoe perspective." Every new shoe model featuring GORE-TEX SURROUND® product technology is subjected to a battery of tests at one of the brand's three footwear labs around the world. There, the shoe enters a process that checks whole boot (or shoe) comfort, waterproofness and flex. "In an average year we test 3,500 pairs for our style qualification process and another 3,500 pairs through audits," Purner said. "We also provide key testing equipment to our factories so they can monitor the waterproofness of the footwear being made daily." Some of that equipment includes a centrifugal tester where boots are filled with water and spun at high speeds. The resulting pressure forces water through any holes that would become leaks in finished footwear. Labs also use an artificial "sweating" foot, which is placed in the shoe to test moisture loss. And as the brand evolves—for instance, the introduction of GORE-TEX SURROUND® product technology, which allows for breathability through the sole as well as the upper part of the shoe—so do the testing measures at its labs and partner and client facilities. As for walking a mile? That's gone high-tech too. All GORE-TEX brand styles must pass the mechanical boot flex test, in which mechanized feet flex the prototype shoe up to 200,000 times to simulate about 250 miles of walking. To add an extra stressor, the test is executed partially underwater. Sure, it's a lot of work, but the first step in meeting customer expectations—especially when your customers expect high-level waterproof performance in a comfortable package—is putting on their shoes.

You may also enjoy

View all articles in this category

Walking

The Rise of the Forest Kindergarten

Stream-side schooling? Read how some curriculum is ditching stuffy classrooms for lessons and learning completely outdoors. This is kindergarten redefined.

Walking

GORE-TEX SURROUND® Footwear: Next Generation Innovation

The shoe looks like it could be a bad idea. When you flip it over, you can’t help but fixate on the holes piercing through the rubber. They look about as watertight as a colander.

Walking

Patch Wilson: Detoured, Not Deterred in Cochamó, Chile

“She told us about these crazy waterslides and pristine rivers, epic campgrounds and insane granite climbing faces. The place sounded so amazing we had to go and check it out for ourselves.”